| Home | Open Account | Help | 360 users online |

|

Member Login

Discussion

Media SharingHostingLibrarySite Info |

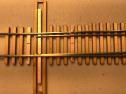

Model Railroading > Fast Track Hand laid switchesDate: 07/15/19 08:13 Fast Track Hand laid switches Author: dmaffei Spent the weekend working on the Shasta division in Redding CA building these and watching the tutorial Fast Track has on line. Looking for any ideas we may be missing. This system sure builds a nice switch.

https://www.handlaidtrack.com/ Web site Edited 1 time(s). Last edit at 07/15/19 08:17 by dmaffei.    Date: 07/15/19 09:01 Re: Fast Track Hand laid switches Author: TCnR Seems like Fast Track picked up the market after Walthers/Shinohara gave it up and left the building. People seem to have just decided to go that little bit further and roll their own.

Date: 07/15/19 09:13 Re: Fast Track Hand laid switches Author: SPDRGWfan Ah, so that's what the fast tracks jig looks like. Pretty cool.

Date: 07/15/19 09:15 Re: Fast Track Hand laid switches Author: dmaffei 4thDistrict Wrote:

------------------------------------------------------- > Dave, make sure you make cuts through the rails > between the points and the frog to isolate the > frog. I think that was step 12. We need to get a jewelers saw as we didn't want to use a cut off wheel Rick. These switches take time, but if operations are as good as your layout, it's worth it.  Date: 07/15/19 15:59 Re: Fast Track Hand laid switches Author: railstiesballast Dremel (and others?) makes cutoff blades in thin and wider thicknesses, I use the thinnest one.

As long as you have a solid grip on the power tool they don't break very often. A safety procedure is to run any abrasive wheel up to operating speed away from and work for a moment, then let it stop, then go to work. This will let the wheel self destruct if it has been damaged in handling without you looking closely at the work and then having it fail. Always, always use safery goggles, I keep my pair right with the power tool. Date: 07/15/19 16:10 Re: Fast Track Hand laid switches Author: towazy I have built over 100 turnouts using the Fasttracks jigs in various sizes. One reccomendation I would make is to add a couple of extra PC ties, primarily in the area of the gap past the frog,as there is only one PC tie holding the rail after the gap is cut. It’s not completely needed,especially if you put it on the layout right after building,but I built many turnouts in advance and found some where the rail past the frog had broken off due to handling. Two PC ties solved that issue.

I also used solid points as opposed to hinged,so I put an extra PC tie in between the frog and the tie where the points flex just to keep the gauge equal in the diverging route. Other than that,these jigs are awesome and a timesaver from scrathbuilding in total,which I used to do. Tom Date: 07/15/19 16:48 Re: Fast Track Hand laid switches Author: jburek I was taught years ago how to build my own from scratch, though I will use some of Fast Tracks jigs to cut correct frog angles & to do the points but I spike it all in on wooden ties & use a PC board tie just for the points. I find it much easier to adjust guage & fine tune these without having the stock rails soldered directly to PC Board ties. I also believe stock rail soldered directly to the ties will not allow the rail to contract & expand accordingly with temperature changes.

Date: 07/15/19 18:24 Re: Fast Track Hand laid switches Author: DKay I love their jigs.I invested heavily on On3 ones.

Regards,DK Date: 07/15/19 20:10 Re: Fast Track Hand laid switches Author: Frisco1522 I don't think Fastracks was in business when I built my yard and engine terminal. I would have invested in the fixture instead of scratchbuilding so many in place.

Date: 07/15/19 21:40 Re: Fast Track Hand laid switches Author: RailThunder I just got mine in about a week ago and plan to start building in a couple weeks. Enjoying all the additional suggestions. One suggestion I have is don't make a huge order all at once with them as when it goes through customs you could get caught paying a customs fee. UPS charged me twice and I'm still fighting that.

Date: 07/16/19 07:40 Re: Fast Track Hand laid switches Author: dmaffei Thanks to all for the input and ideas folks. Exactly what we were looking for. As I said, these switches come out awesome. A great system and on-line tutorial help that walked us through the build and got us going...

Dave Date: 07/20/19 18:05 Re: Fast Track Hand laid switches Author: NCA1022 Maybe I missed it but I thought you need to cut a gap in the throwbar, like the gap in the adjacent PC ties. Otherwise you could have a short.

- Norm Date: 07/20/19 22:53 Re: Fast Track Hand laid switches Author: dmaffei A1022 Wrote:

------------------------------------------------------- > Maybe I missed it but I thought you need to cut a > gap in the throwbar, like the gap in the adjacent > PC ties. Otherwise you could have a short. > > - Norm Good eye Norm. In photo two above showing the switch points, we need to drill a hole for the Switch machine rod and cut insulation gags on either side. You must have done this before. We have corrected that issue on that switch. Dave |